Overview

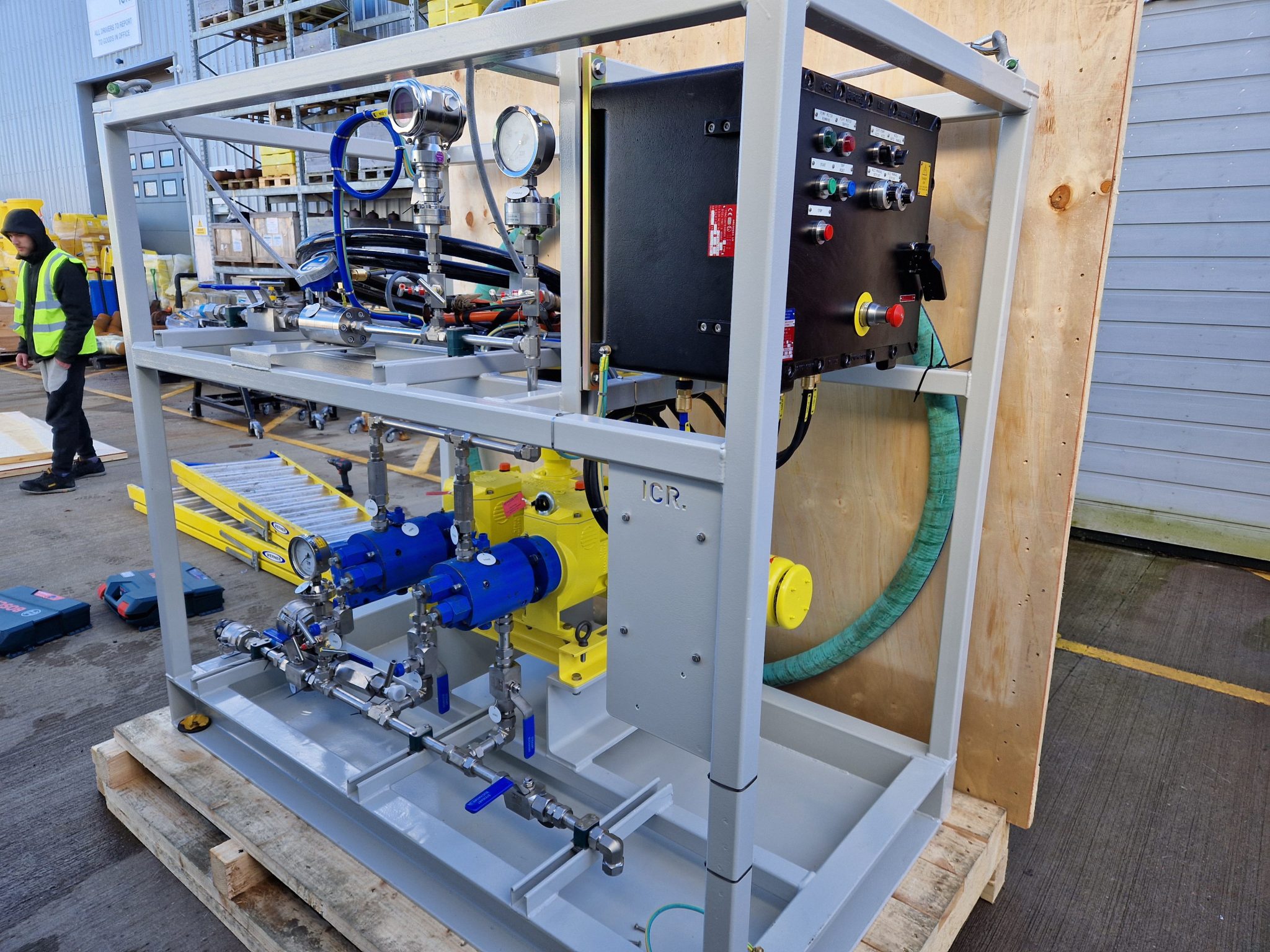

ICR’s provision of pneumatic, electric and solar-driven chemical injection pump services caters to a wide range of injection rates, pressures, chemical duties and environmental factors. All packages are designed, built and tested to industry standards and client specifications.

Whether our clients require a short-term, long term or permanent solution, ICR can deliver. Our range of services include:

– Rental and Sale of Chemical Injection Packages

– Engineered Design and Build of Bespoke Turnkey Injection Packages

– Equipment and Spares Supply

– Manpower Services including Surveying, Repair, Maintenance Programmes & Commissioning

– Customer Training and Technical Support

All chemical injection packages are tested and certified inhouse by our team of specialists. Systems and ancillaries are Atex-2 rated as standard, and are supplied with Functional & Hydro certs, Pressure Relief Valve certs as well as Operations and Maintenance Manuals.

Rental Services

Rental Chemical Injection Systems provide our clients with a flexible, maintenance-free solution to their chemical injection requirements. An alternative to Capex spend, rental systems provide a highly cost-effective approach to pump management. ICR’s standard rental service includes:

– Newly certified injection skids provided annually

– Back-to-Back replacement units, allowing skids to be replaced onsite, minimising downtime

– Immediate spares and breakdown cover

– 24/7 Technical Support

– Testing & Inspection

– Chemical Injection Maintenance Register

– No unnecessary CAPEX Spend

– Upgrades or modifications inclusive with package

Engineered Systems

ICR’s inhouse engineering team specialise in the design, fabrication and delivery of bespoke, turnkey chemical injection solutions. Be it fully automated or manual, pneumatic or electric-drive, ICR packages can be spec’d to include tanks, mixers, sensors and all other types of instrumentation. Designs and builds are delivered in a variety of materials to account for chemical compatibility and environmental factors.

Our Engineering team supports our clients throughout the entire project lifecycle:

– Front End Design Consultancy

– Comprehensive Engineering

– Fabrication & Testing

– Installation & Commissioning

– Maintenance & Upgrades

Spares & Servicing

ICR are authorised distributors of Williams and Milton Roy Pumps as well Kenco Engineering products. At our facility in Aberdeen, we carry the largest inventory of these products outside of USA, available for near-immediate dispatch.

ICR also hold stock of an extensive range of alternative pump options, consumables, ancillaries, valves, fittings and hoses. A one-stop shop for your chemical injection needs. are qualified to service and repair Williams & Milton Roy products, including cover under manufacturer warranty.

Benefits

With over 25 years of global expertise, we offer newly certified injection skids, immediate spares, breakdown cover, and back-to-back service to minimise downtime. We are committed to excellence and provide comprehensive testing, inspection, and maintenance register services, ensuring optimal performance and longevity. Our engineered project build solutions cover front-end design consultancy, comprehensive engineering, fabrication, testing, installation, commissioning, and ongoing maintenance and upgrades.

As an authorised distributor for Kenco Engineering and Williams Pneumatic Air Driven pumps, we boast the largest stock of spare parts outside of North America, facilitating rapid response and competitive pricing. Our customer-focused approach is underscored by a dedication to no unnecessary CAPEX spend, offering inclusive upgrades or modifications. Key benefits for our clients:

- Annual provision of newly certified injection skids

- Immediate spares, breakdown cover, and back-to-back service for minimized downtime

- Comprehensive testing, inspection, and maintenance register for optimal performance

- No unnecessary CAPEX spend with inclusive upgrades or modifications, ensuring cost-effectiveness

Case studies

Send us your enquiry

Please complete the form below, and a member of our team will be in touch as soon as possible. Alternatively, please send your enquiry directly to sales@icr-world.com