Quickflange™ Weldless Connectors

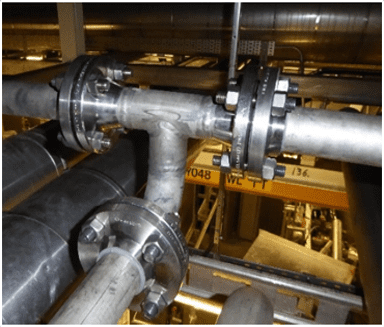

Latest Case Study: Quickflange™ 6” Hydrocarbon Line Decommissioning

New Certifications from Lloyd’s Register & LRQA

High performance weldless flange to pipe connections

For over 20 years, Quickflange™ has revolutionised flange-to-pipe connections by providing a permanent and mechanically robust alternative to traditional welding.

Our technology ensures rapid and safe installations eliminating hot work providing a cost-effective solution for improving pipeline integrity and flow assurance.

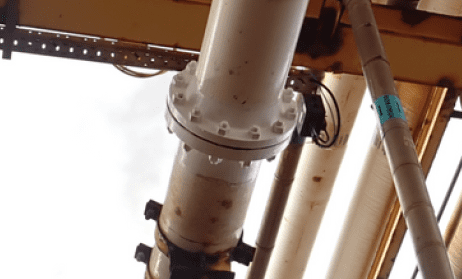

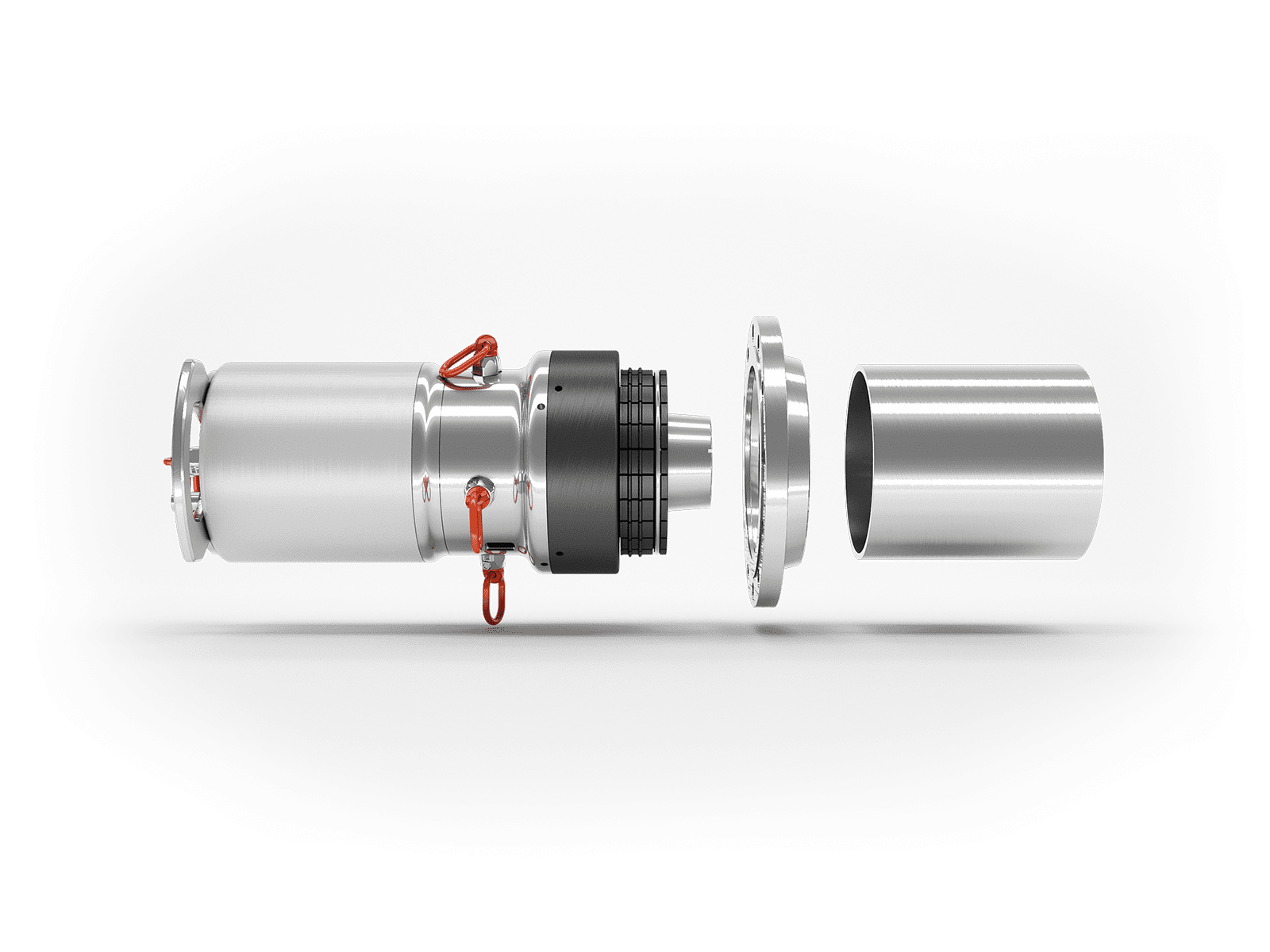

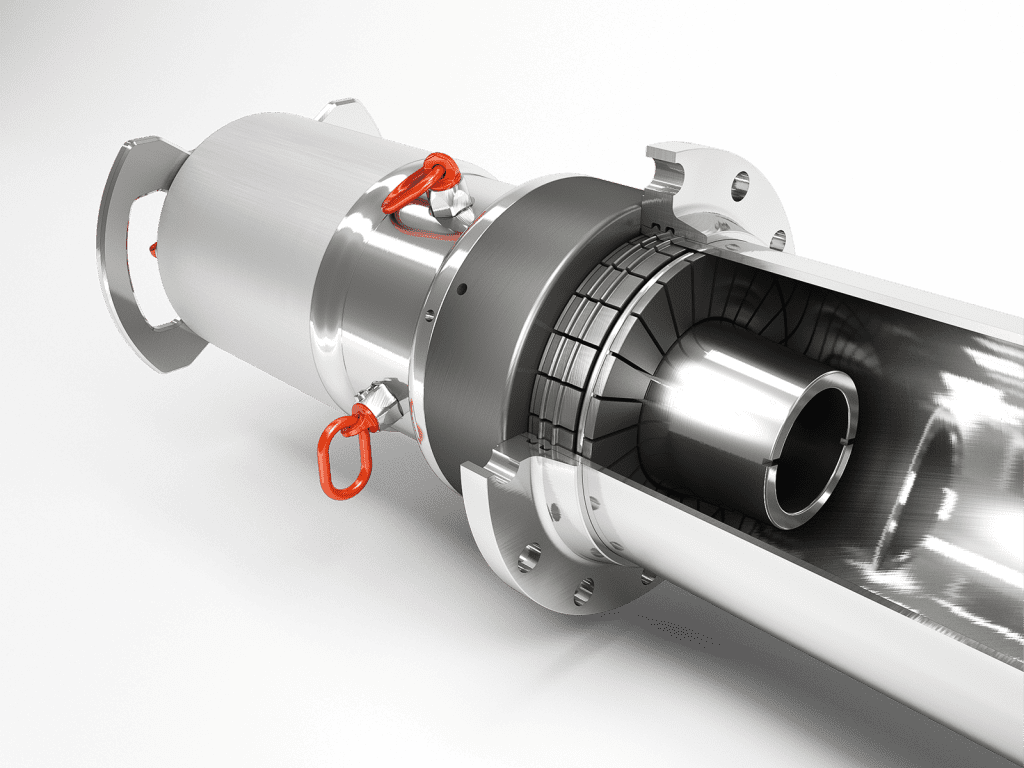

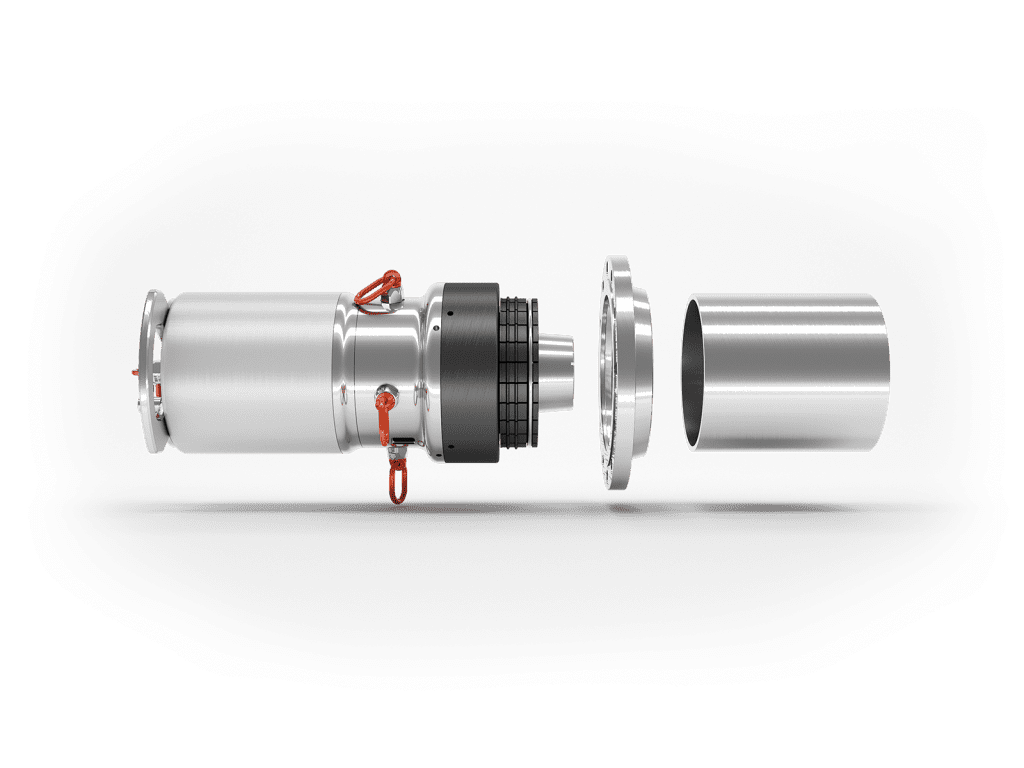

ICR’s Quickflange™ weldless technology utilises a modified standard flange where patented internal grooves are machined in such a way that it slides over the pipe end. By combining our Quickflange™ connector with our bespoke Quickflange activation tool, the process of installing a Quickflange weldless connector is both quick and easy.

Installation made easy

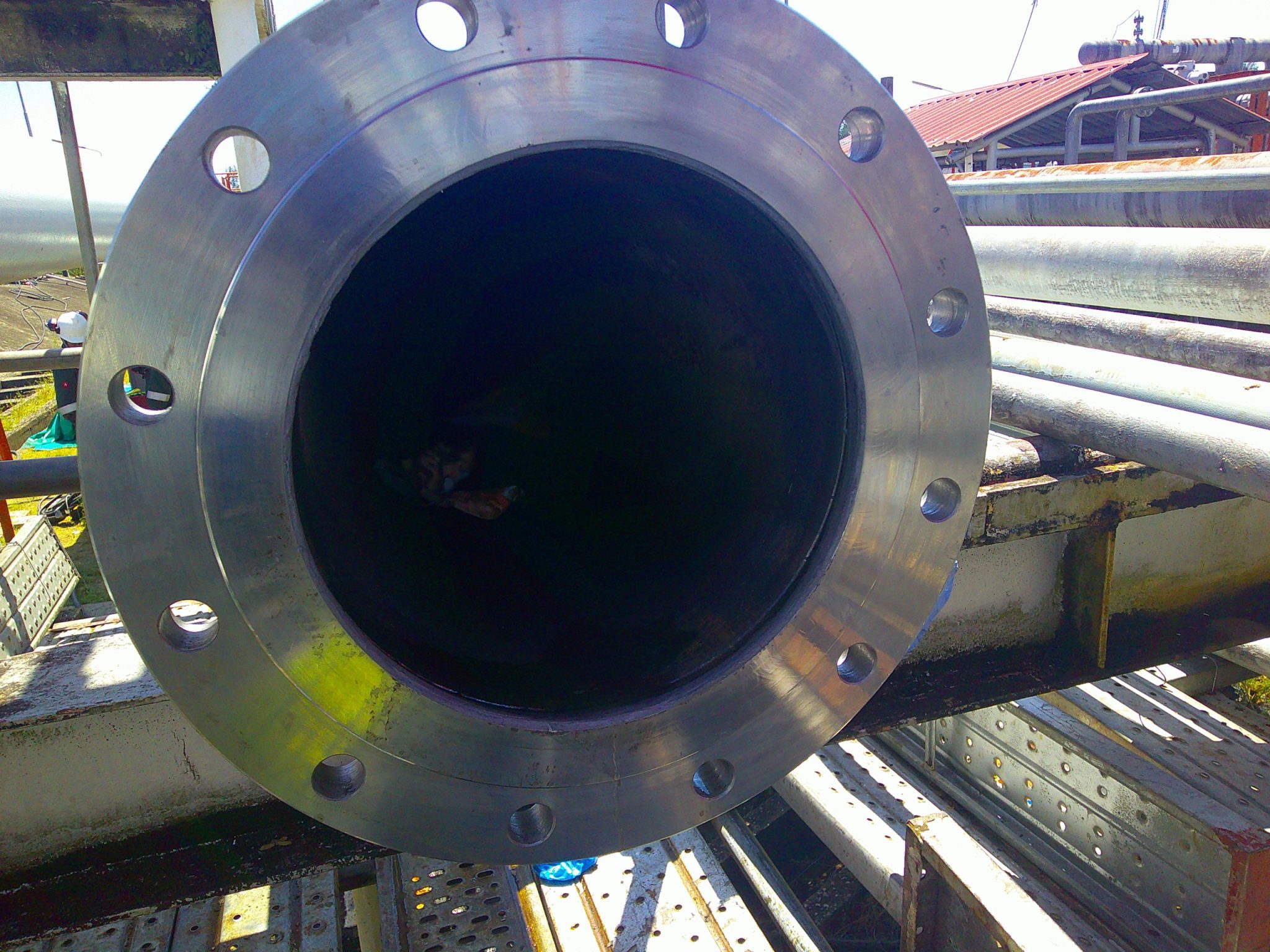

Upon isolating the line and ensuring a straight cut is achieved to the pipe, Quickflange™ sits flush to the pipe edge. Our hydraulic tool is aligned into the pipe and activated to the required pressure.

The tool’s quick extension flares the segments, swaging the pipe into the pre-machined grooves of the Quickflange™ connector. A simple reversal of the tool concludes the installation, creating a permanent gas-tight seal.

Varied product range

Our connectors cater to a wide range of pipe sizes, pressure classes, and – most crucially – material types that can be challenging for traditional welding methods.

Size Range: ¾” to 14”

Material Range: Carbon Steel, Stainless 316, Duplex, Super Duplex, 6Mo, Copper-Nickel & Nickel Alloy.

Pressure Range: 150# to 900#, available up to 2500# on request.

Type Approvals: DNV & ABS

Over 20 years proven track record.

Quickflange™ has passed a design appraisal with LRQA demonstrating conformity with the Pressure Equipment Directive (2014/68/EU). Quickflange™ can be considered for incorporation into CE-marked assemblies and pressure systems ranging from Category I to Category IV.

In 2025, Quickflange™ was awarded new certifications from Lloyd’s Register and LRQA. The successful completion of these certifications, which include a Pressure Equipment Directive (2014/68/EU) Conformity Assessment by LRQA (March 2025) and Type Approval from LR (June 2025), follows a rigorous programme of technology evaluation, testing, and third-party audits initiated in early 2024.

| Dimensions | |

|---|---|

| Pipe Size | 3/4” to 14” |

| Pipe Wall | Sch10 – Sch160 |

| Pressure Rating | 150# to 900# (up to 2500# available on request) |

| Pipe Material | Carbon Steel, Stainless Steel (316, 6Mo, 22Cr, 25Cr), Copper-nickel Nickel alloy |

| Flange Geometry | ASME B16.5; EEMUA 145; EN 1092-1 |

| Technical Features Include: | No heat, no spark, no hot work Permanent full-strength connections Activated in minutes Light and simple one part design Crevice corrosion protection DNV Certified Installations Zone 1 and 2 |

Benefits

- Permanent solution

- 100% coldwork solution with ZERO emissions

- 80% time saving over traditional welding methods

- Over 20 years of experience and a proven track record

- Industry-recognized approval with our DNV and ABS Type Approvals

- Access to ICR’s highly trained, multi-skilled global technicians

- Third-party training for clients and partners globally

- Off-the-shelf product ensuring fast turnaround particularly for urgent repairs

What we can repair

- Hydrocarbon gas and liquid systems

- Remote locations using rope access

- Close proximity to heat-affected zones

- Pipework modifications and re-routing

- Pipework construction

- Decommissioning

- New spool tie-ins

- Blinding of lines

- Replacement of existing flanges

- Onshore and offshore capabilities

Confined Spaces

Remote Locations by Rope Access

Piping Repairs

Close Proximity to Heat Affected Zones

Hydrocarbon Gas and Liquid Systems

Pipework Modifications

Pipework Construction

Decommissioning

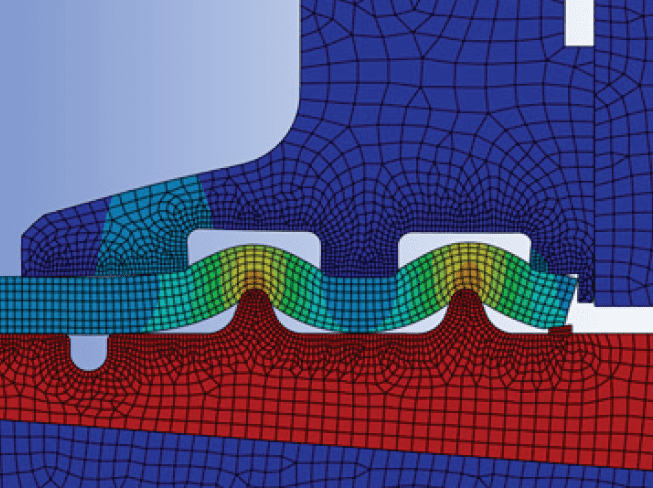

Design-by-Analysis for Out-of-Specification Piping

Quickflange™ is engineered for use on both new installations and existing piping systems. While the connector design and tolerances for the mating pipe typically satisfy most application requirements, there are cases where conditions fall outside the qualified range and additional consideration must be given.

To assess the suitability of Quickflange™ connectors in these scenarios, our engineering team can utilise 2D Axisymmetric Finite Element Analysis (FEA) to verify the joint integrity.

Case Studies

Send us your enquiry

Please complete the form below, and a member of our team will be in touch as soon as possible. Alternatively, please send your enquiry directly to sales@icr-world.com