Date: July 2022

Client: Petrofac

Location: Southern North Sea

Client challenge

Petrofac, a leading international service provider to the energy industry, faced issues with injecting chemicals at the optimal rate into their unmanned platform. They needed to inject scale and corrosion inhibitors into their production and gas export flowlines respectively to create atomisation. However, they were experiencing ongoing blockage problems with the incumbent injection devices which needed to be replaced. As a result, Petrofac consulted our corrosion monitoring team to advice on a suitable modification to replace the existing injection devices and avoid prolonged shutdowns with escalating costs. Failure to accurately inject the chemicals would result in inadequate corrosion control, a threat to plant integrity and personnel safety, and potentially poor-quality gas being exported rendering it unsellable.

What we did

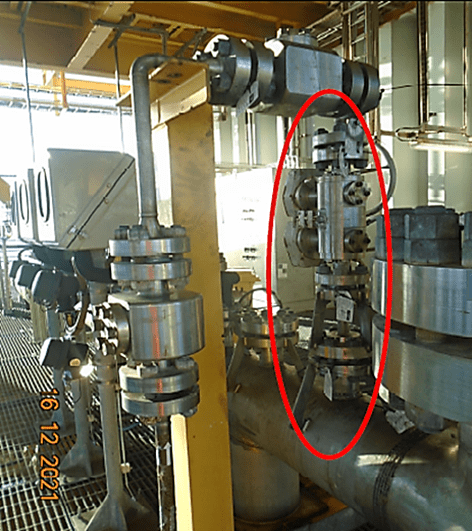

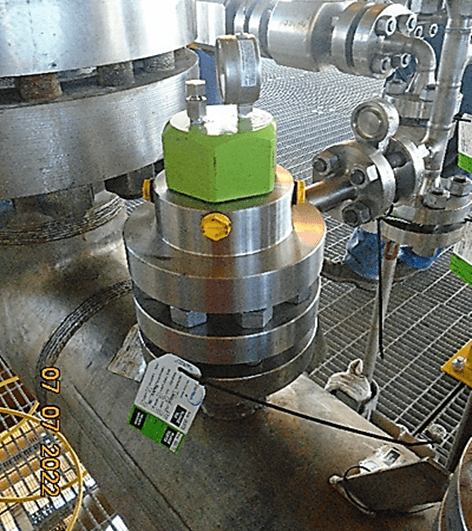

Blockages typically necessitate a shutdown. Our team carried out an initial survey to identify the existing flanged connection specifications, then we recommended the current set up is replaced with RTJ flanged hydraulic chemical injection access fittings with flanged side tee. This will enable nozzle replacement online with the specialist retriever tool.

Results

We successfully guaranteed subsequent blockages will no longer require platform shutting down for replacement saving on costs.

As a result of our work, the chemical injection was more controlled, resulting in a better quality of gas.