Client: Major North Sea operator

Location: Central North Sea

Scope

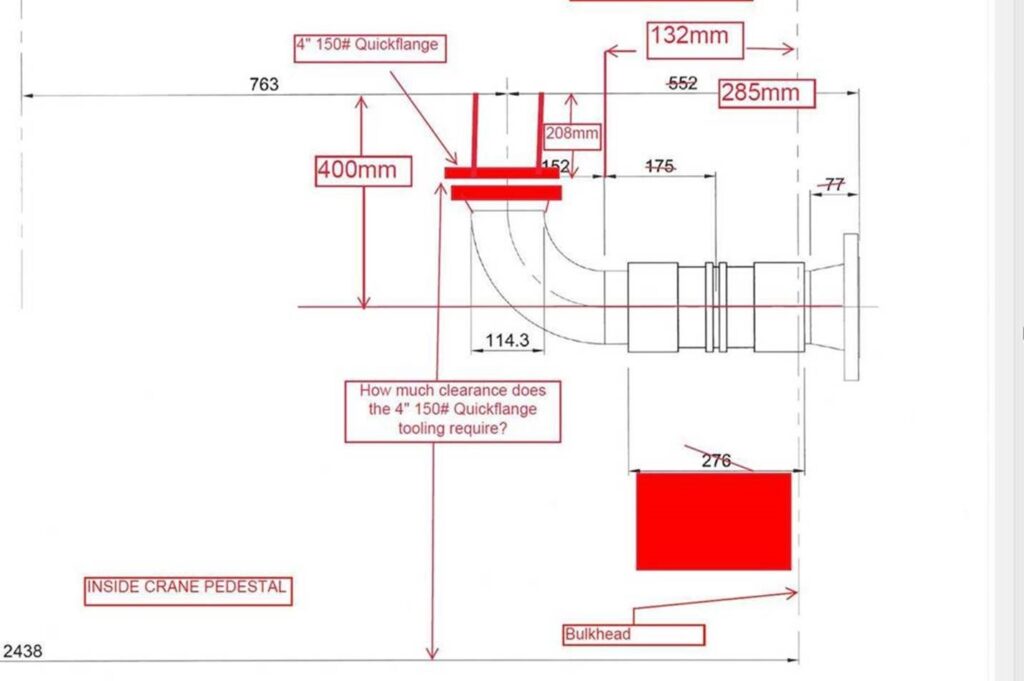

Quickflange™ technology was identified to repair a leaking 4” Sch80 carbon steel nozzle feeding from a diesel tank. Hot work was not an option due to both time constraints and the extreme space restrictions with the nozzle being located in a void which was too small for a welding habitat.

Solution

ICR’s standard installation equipment was mobilised, which was able to contend with the tight clearance, limited rigging options and space restrictions – having only limited clearance to the nearest I-beam obstruction. The technician mobilised was ‘confined space entry’ trained in order to complete the install in a safe manner. All items were mobilised within 48hours, minimising the client’s downtime. The Quickflange™ joint was also tested post installation, to ensure the integrity of the connection and that it conformed to industry and client standard.

Results & Benefits

- No hot work

- Extreme space restrictions were met with no issues, something no other competitor could match

- Equipment mobilised 48hours from initial request

- Reduced cost due to minimal downtime