| Date | Client | Location |

|---|---|---|

| May 2021 | North Sea Oil Platform | UKCS |

Scope

A through wall defect with a hydrocarbon leak on a 3 in NB pipe on an offshore platform export piping system causing a shut down.

The client approached ICR for a solution to encapsulate and seal the leaking defect.

Design parameters

Process medium: Hydrocarbons

Design Pressure: 138 bar

Design Temperature: 120°C

Solution

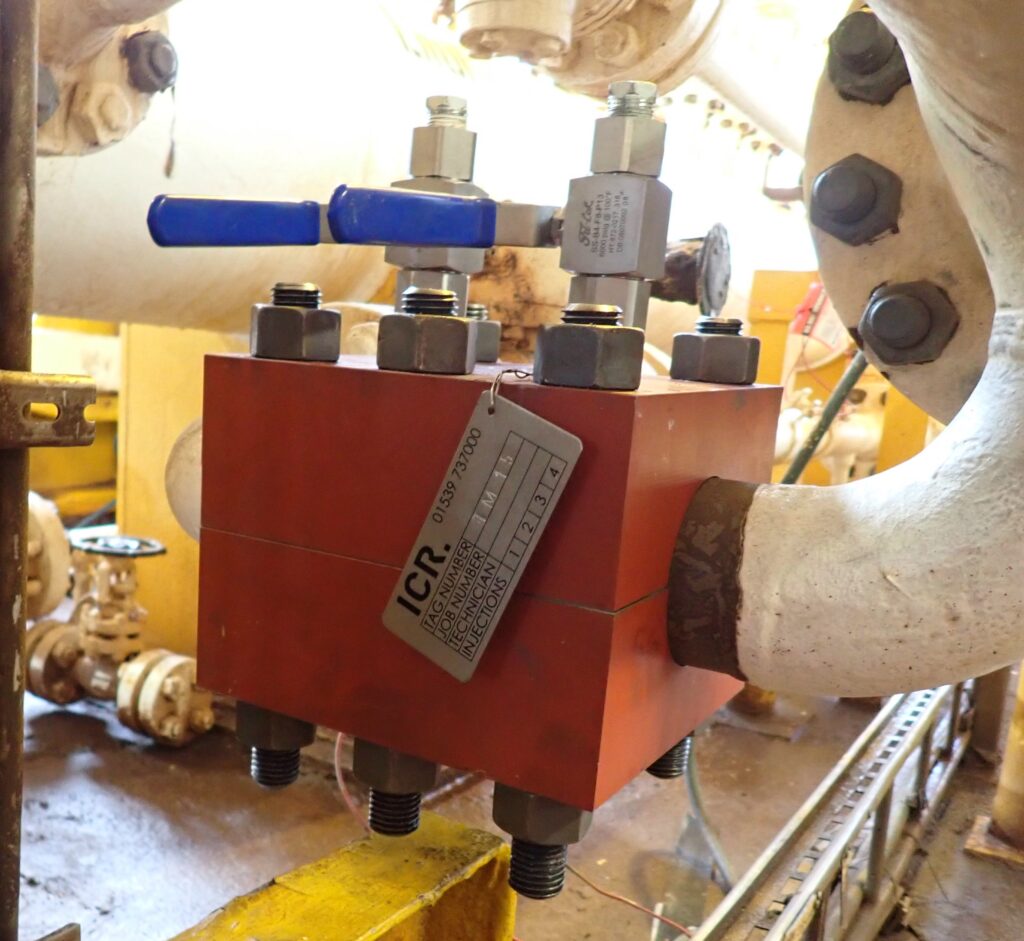

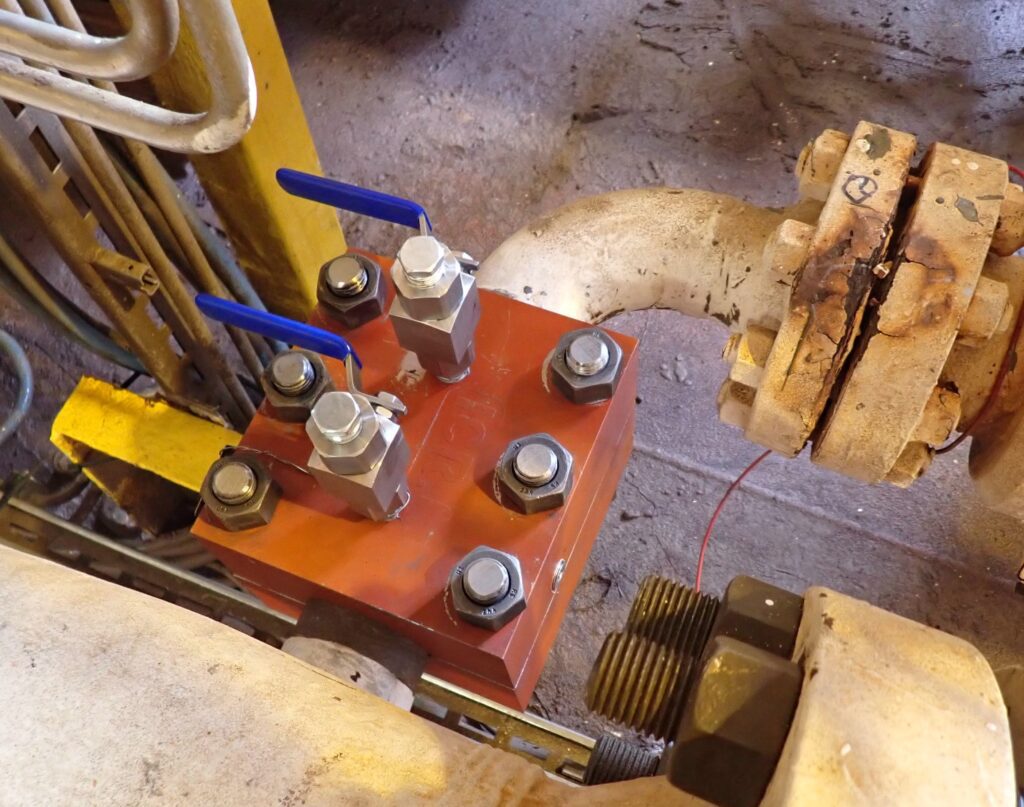

A composite repair was considered and discounted in favour of a mechanical repair clamp to enclose the defect. The repair clamp was designed to provide full pressure containment of the leaking line contents.

The repair clamp utilised an single elastomeric seal system energised around pipe, the sealing boundary then runs around the joint face of the split clamp sealing around the circumference of the pipe. The main cavity of the clamp was injected with a two part high density flexible sealant.

Prior to deployment to the platform, the clamp was successfully pressure and function tested in-house at ICR.

The repair clamp was manufactured and delivered to the client in 4 days from the award of contract. ICR technicians were mobilised to carry out the installation and testing, the scope completed in 7 days from contract award, several days ahead of the clients original target.

Results & Benefits

- Customer line integrity reinstated, leaking product fully enclosed

- Installation able to start up without the additional delays associated with a hot work repair

- Finished ahead of schedule

Featured articles

University of life stands Govan-raised engineer in good stead

ICR Group shortlisted for Business of the Year