Improved methods for inspecting, repairing, and maintaining assets and critical infrastructure

Explore solutions

Latest Case Study: Quickflange™ 6” Hydrocarbon Line Decommissioning

Latest Case Study: I-Beam Repairs – Offshore Malaysia

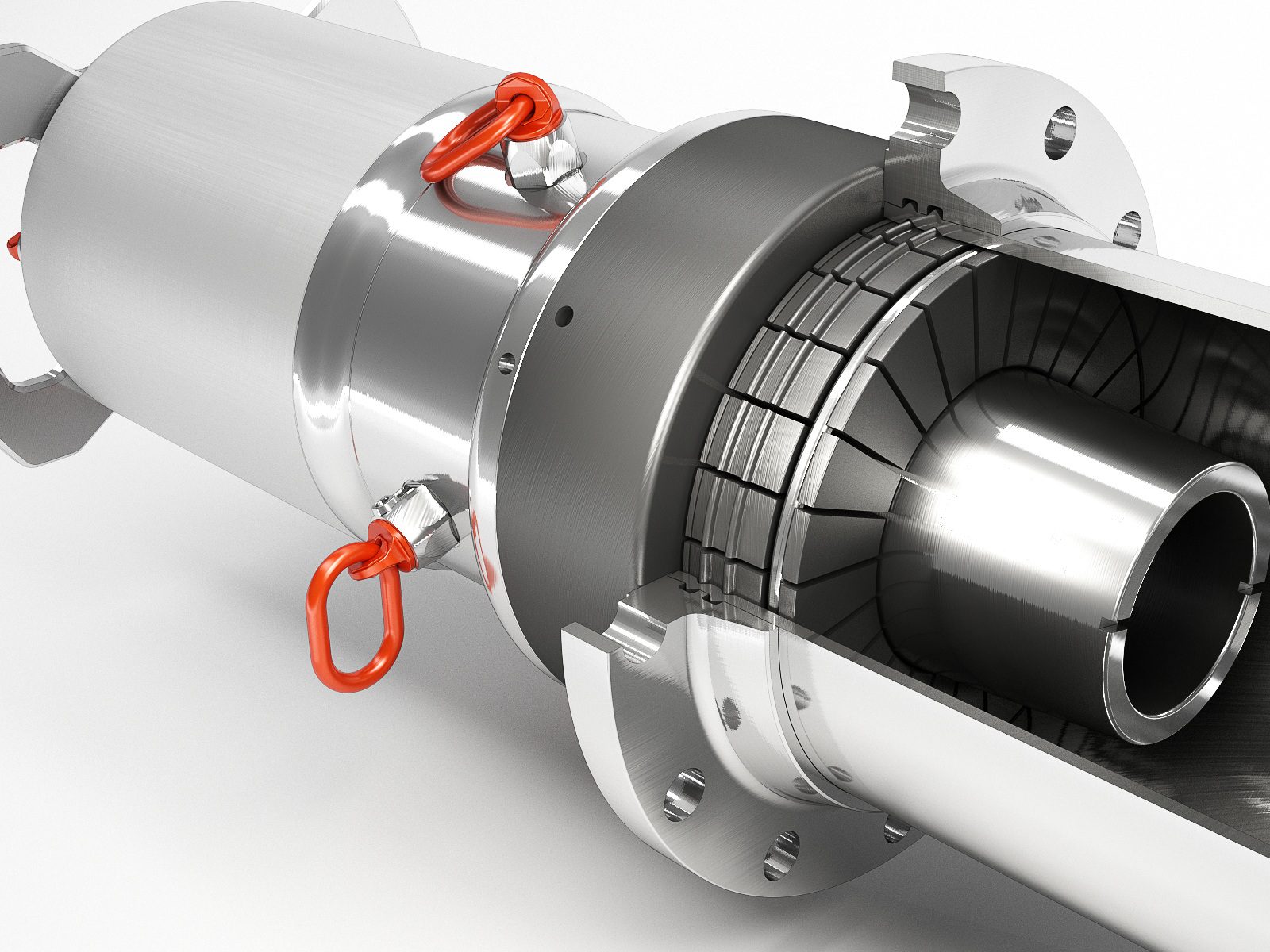

Latest Case Study: Sidestream Unit for Roemex

CIU has designed and delivered a bespoke sidestream unit for Roemex which will be used within its produced water system.

Read more

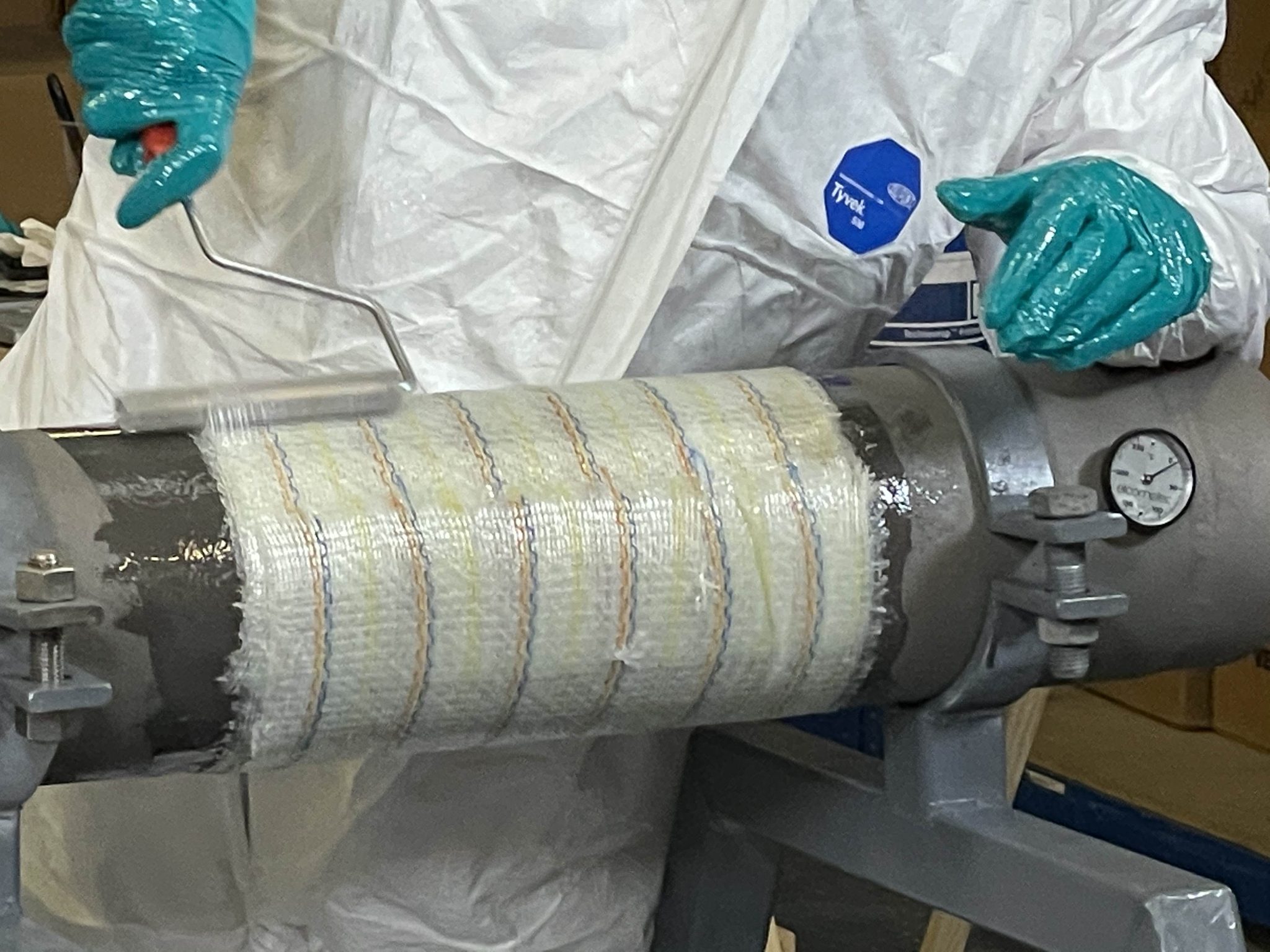

Composite Repairs for Marine Industry

Technowrap™ can address common corrosion challenges caused by weathering, load fatigue, material degradation, ageing fleets, and more, and can repair a wide range of defect types, including thin- and through-wall, as well as internal and external corrosion.

Find out more

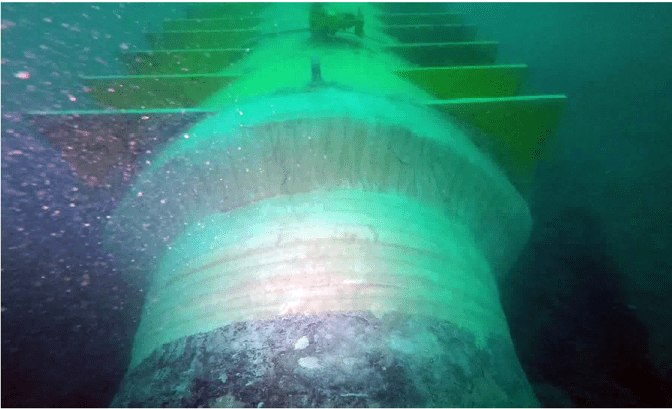

Subsea Composite Repairs

Discover our proven subsea composite repairs, capable of restoring pipeline integrity with 20-year performance.

Learn more

Asset Decommissioning & Late Life Support

With a proven track record in supporting assets in late life and decommissioning stages, and a suite of cost-effective technologies at its disposal, ICR Integrity is well-positioned to support operations faced with the complex challenges associated with asset shutdowns.

Read more