Date: March 2023

Client: Chemical Supplier

Location: Wales

Client challenge

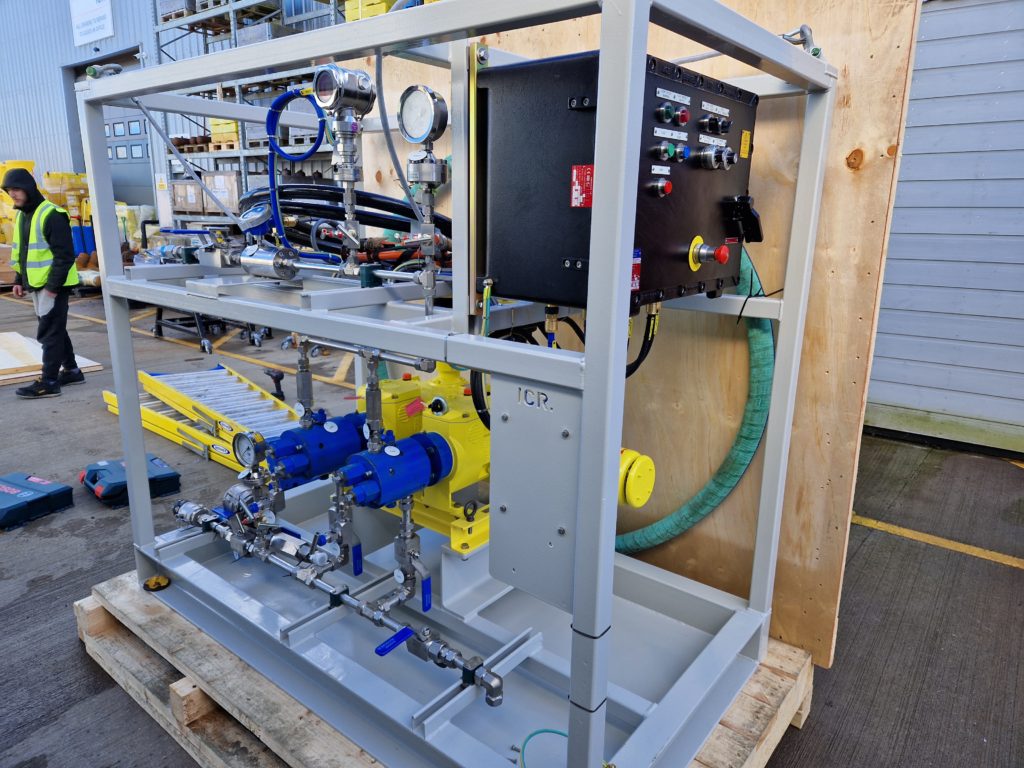

Our client required a Super Drag Reducer Injection Package to handle a chemical with high viscosity which had the potential to impact pump performance. Due to varying process parameters, a solution was needed to automatically adjust injection rates and maintain constant concentration, regardless of flow and pressure variations in the pipeline. The goal was to provide a fully automated system that allowed remote control of pump operations with minimal input required.

The high viscosity (100,000 cP) of the chemical posed a significant challenge in maintaining consistent injection rates as the varying process parameters further complicated the task of ensuring a constant concentration. Our team was asked to design a chemical injection skid with an innovative solution that would automatically adjust the pump stroke length via an Actuator Capacity Controller (ACC). This approach aimed to achieve reliable and automated control of injection rates, enabling automatic pump control remote pump control and ensuring efficient chemical injection.

What we did

To address these specific requirements, our team developed a comprehensive solution encompassing the following key elements:

Automated injection rate adjustment: The design of the chemical injection skid incorporated an Actuator Capacity Controller (ACC) that was capable of automatically adjusting the pump stroke length. This innovative feature allowed for precise control of injection rates, ensuring a constant concentration, regardless of variations in flow and pressure within the pipeline.

Integration of on-skid flow meter and control panel: The ACC was seamlessly tied into an on-skid flow meter and control panel, providing real-time monitoring of flow conditions. This integration facilitated automatic adjustment of injection rates based on the measured flow, ensuring accurate and consistent chemical injection.

Remote pump control: The automated solution enabled remote start and stop functionality for the pumps, allowing the client to control operations remotely without the need for additional input. This feature provided convenience and flexibility in managing the injection process.

Results

The successful implementation of the Super Drag Reducer Injection Package effectively met the challenging requirements posed by the high viscosity of the chemical, enabling efficient and reliable chemical injection. The automated system also allowed for the automatic adjustment of injection rates based on flow conditions, ensuring a constant concentration, regardless of variations in flow and pressure within the pipeline. This provided consistent chemical treatment and optimised performance.

Our client expressed satisfaction with our solution, highlighting its effectiveness, reliability and first-class service and support provided by our team throughout the project.

The Super Drag Reducer Injection Package exemplified our team’s expertise in designing and delivering automated solutions for challenging chemical injection requirements. By incorporating the Actuator Capacity Controller (ACC) and integrating it with on-skid flow monitoring and control systems, we achieved precise and adaptive injection rates, enabling remote pump control and consistent chemical treatment. Our client benefitted from a reliable and efficient solution that not only met their specific needs – but also led to a 60% reduction in power usage (which will increase in the winter) – and received exceptional service and support throughout the project lifecycle.

Client quote:

“To sum up, amazing! We have seen a 30% increase in flow through pipeline at 50 ppm, they do not have to use booster pumps now, and pressure drops across the pipe is reduced. They actually have to gag the flow at the terminals at points because there’s too much! All looking very positive, and the skid pump has been used regularly with no problem. It will be in continuous use today, and tomorrow.”

Featured articles

University of life stands Govan-raised engineer in good stead

ICR Group shortlisted for Business of the Year