Scope

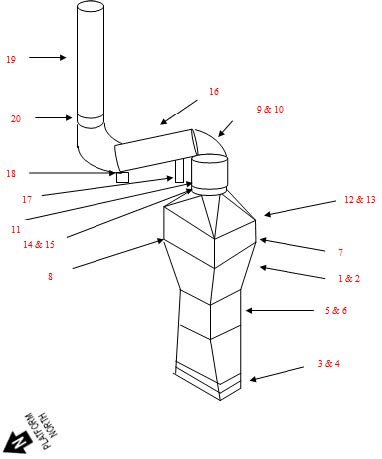

As a result of an ongoing asset life extension study the client had a concern regarding the condition of exhaust stacks located on a 25 year old offshore production platform. The main concern related to potential cracking/hot spots within the exhausts which may in turn be causing temperature anomalies on the surrounding support structure.

Solution

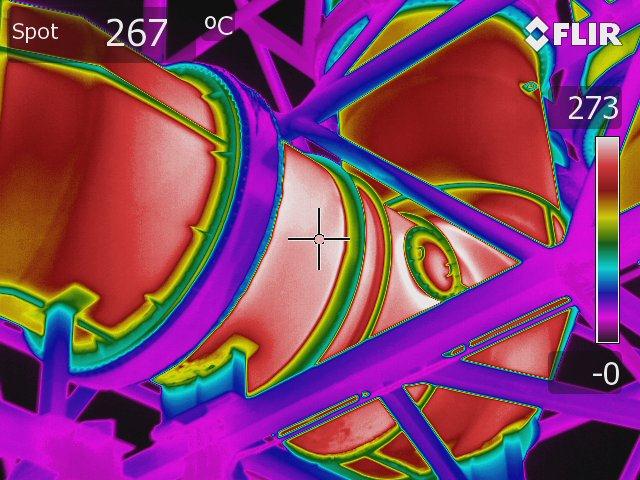

Thermographic and digital images were taken at various points identified around the exhausts to deliver as much information as possible, relating to their overall condition, and report on any identified temperature anomalies located within the surrounding support structure.

The location of the exhaust stacks in question required detailed discussion and agreement with the client on the whereabouts of suitable and safe areas where ICR’s trained Thermographer could take optimum and concise images from. An initial site survey of the area to be inspected was undertaken by a multi-skilled ICR Technician during a routine corrosion monitoring scope of work some months previously.

This site survey was used as basis for discussion and an agreement was reached upon suitable safe locations for the inspection to take place. These included deck levels immediately adjacent to the exhausts and the platform helideck. It was agreed that no additional scaffold construction would be required for the inspection.

Utilising a state of the art infrared thermography camera, the technician carried out the inspection during normal operation of the associated turbine units. Both digital and infrared images were taken of the exhaust at each pre-agreed inspection location and these were presented to the client in a detailed report format.

Results & Benefits

- Inspection showed that the carbon steel exhaust ducting appeared to be in good condition with no signs of cracking or porosity. The flexible flanged area on the horizontal section of stack was found to be in poor condition.

- The structural support beams were also found to be in good condition with heat sources discovered on the section closest to the stacks. This is thought to be due to coating deterioration.

Featured articles

University of life stands Govan-raised engineer in good stead

ICR Group shortlisted for Business of the Year